Complete set of wire heating equipment

1、 PC steel bar production line

The PC steel bar production line, also known as the prestressed concrete steel bar production line, is a series of processing methods such as bending, rust removal, drawing, marking, straightening, quenching, and tempering of 30MnSi material steel bars on the production line, so that their various indicators meet the requirements of GB/T5223.3-2005 for pile steel bars.

Our company's PC steel bar production line equipment has reached the domestic level, and the four commonly used specifications have achieved line speeds of:

Specification: 110 meters/minute with a diameter of 7.1mm

Specification of 9.0mm with a diameter of 100 meters per minute

Specification: 70 meters/minute with a diameter of 10.7mm

Diameter 12.6mm, specification 45 meters/minute

Functional structure

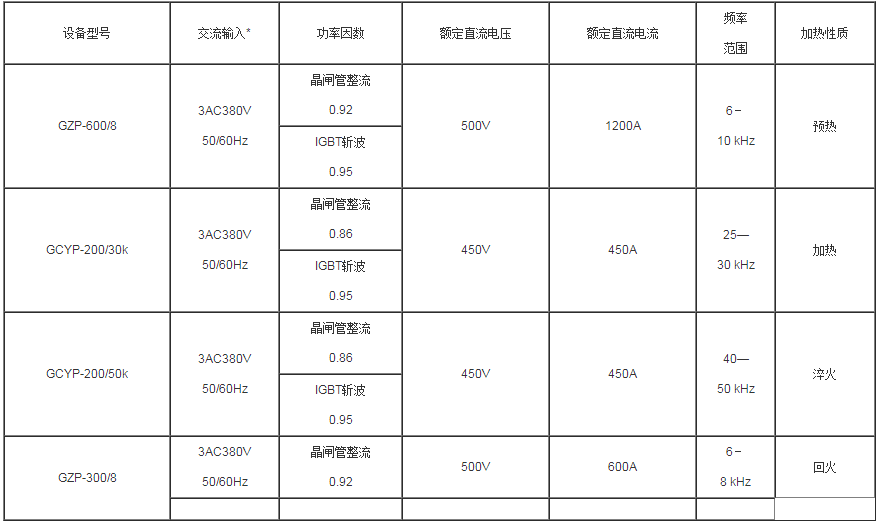

The PC steel bar production line equipment is equipped with multiple intermediate frequency/ultra audio power supplies to complete the pre heating, heating, quenching, and tempering processes of steel bars online; Synchronous control of the production line process is achieved by driving machinery through multiple frequency converters. All power supplies are equipped with parallel IGBT induction heating power supplies. Due to online heating, the working status and synchronization control requirements of the power supply are strict.

The parallel IGBT induction heating power supply adopts an AC-DC-AC variable frequency power supply structure. The rectifier of the power supply adopts three-phase thyristor rectification or thyristor+IGBT chopping method; The inverter adopts a high-voltage high-power IGBT module and a high-power fast recovery diode to form the inverter power unit; The resonant slot adopts parallel resonance.

2、 Cold rolled ribbed steel bar series heating device

Functional structure

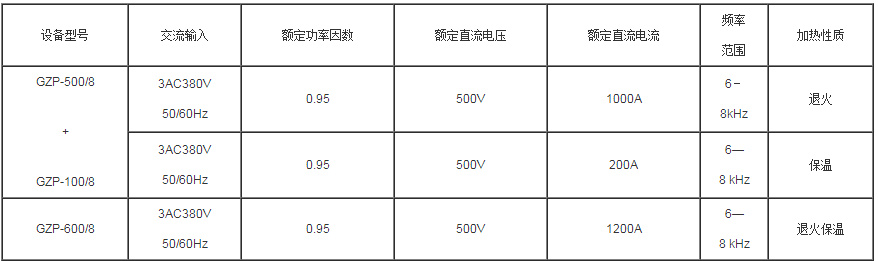

There are two heating power sources for the annealing production line of cold-rolled ribbed steel bars, all of which use parallel IGBT induction heating power sources. Due to online heating, the working status and synchronization control requirements of the power supply are strict.

The parallel IGBT induction heating power supply adopts an AC-DC-AC variable frequency power supply structure. The rectifier of the power supply adopts three-phase thyristor rectification or thyristor+IGBT chopping method; The inverter adopts a high-voltage high-power IGBT module and a high-power fast recovery diode to form the inverter power unit; The resonant slot adopts parallel resonance.

Product features: Energy saving, strong anti rust ability of steel bars, and stable equipment operation.

Main technical indicators

Customizable according to user's power grid

*The power and frequency of the heating power supply can be customized according to user process requirements